Description

The OKC-3S is part of a series of weapon improvements begun in 2001 by the Commander of the Marine Corps James L. Jones to expand and toughen hand-to-hand combat training for Marines, including training in the Marine Corps Martial Arts Program and knife fighting. In the Multi-Purpose Bayonet program, 33 different knives were evaluated. The OKC-3S performed best, or next to best, in nearly all testing categories. A contract for OKC-3S was made in December 2002 and production and distribution began in January 2003.

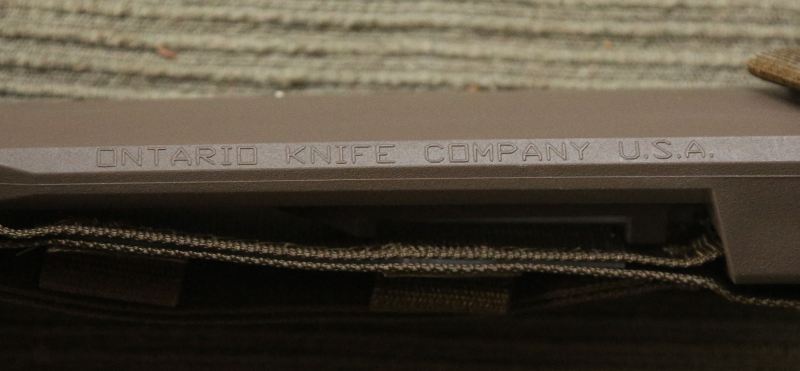

The OKC-3S is manufactured solely by the Ontario Knife Company and identical civilian versions are available for purchase. It bears a resemblance to the Marines’ iconic Ka-Bar fighting knife, though it is not fullered. It is larger, thicker and heavier than the M7 although slightly thinner and lighter than the current U.S. Army-issued M9. A sharper point helps penetrate body armor that many modern adversaries wear; while serrations near the handle help improve its function as a utility knife. In one demonstration, a prototype was able to pierce a punching bag covered with aircraft aluminum and a ballistic vest. The entire weapon is designed to be corrosion resistant, and weighs 1.25 lb (0.57 kg) with its sheath. The scabbard and grip are colored to match the Corps’ coyote tan gear, compatible with both woodland and desert camouflage. The NATO Stock Number is 1095-01-521-6087.

The OKC-3S features an 8 in (20.32 cm) long, 1.375 in (3.49 cm) wide, 0.2 in (0.51 cm) thick blade. The serrations measure 1.75 in (4.4 cm) of the blade length on the true edge. The blade is made from high carbon steel rated at HRC 53-58 and is capable of functioning without breakage in operating temperatures of −25 to 135 °F (−32 to 57 °C). The blade also has a non-reflective phosphate finish.

The grip is made of Dynaflex, a synthetic non-slip material, is ergonomically grooved, and is more oval than round. This design helps prevent repetitive-strain injuries and hand fatigue during training. It also features an embossed Eagle, Globe, and Anchor molded in to allow a user to identify the direction of the blade in the dark. The full tang connects the cross guard/muzzle ring (which is .165 in (0.42 cm)) and pommel latch plate that clasps the barrel lug; both are phosphate coated like the blade. Former Ontario Knife Company president and chief executive Nick Trbovich Jr. said of it: “We spent a lot of time making sure the handle was ergonomically correct… There are no blister points on the handle.”[2]

The polyester elastomer scabbard, designed by Natick Labs, offers a weight and noise reduction from the previous M7 Scabbard and is Molle II compatible. It has a fitted internal stainless steel spring and friction device at its throat to secure the bayonet. A ceramic-coated aluminum honing rod is located on the back of the scabbard. The scabbard is compatible with the MOLLE/PALS modular attachment system.

The bayonet show still has it’s protective coating on the blade.

The info given after Wikipedia.